EDM vs CNC Machining: A Comparative Overview

By PAGE Editor

CNC machining is one of the precise methods to create complex cuts and shapes, but it struggles to machine sharp corners, deep & narrow cavities, intricate internal contours, and micro holes. It is due to the size limitations of cutting tools. Here comes the role of EDM machining, which can machine micro-geometries using custom-shaped electrodes or wire as a tool.

It is important to understand their capabilities, process, and what kind of machining they can do. So, you choose the right technique and manufacture your parts with the desired specifications. In the upcoming sections, we will present a comparative overview of EDM vs CNC machining.

What is EDM Machining?

Electrical Discharge Machining(EDM), also called “spark machining,” uses sparks to machine the electrically conductive materials. Instead of conventional cutting tools, an electrode with the shape of the material to be removed acts as a cutting tool.

A soft metal or graphite electrode and workpiece are immersed in a dielectric medium. When electricity passes, it creates an electric discharge and erodes the material precisely.

There are three types of EDM manufacturing processes: Die Sinker EDM, Wire EDM, and Hole Drilling EDM. Each of these uses a different shape of electrode and is suitable for specific jobs. Sinker EDM uses a custom-shaped electrode. EDM machining services are suitable for complex cavities, profiles, and corners, especially in molds & dies.

Wire EDM uses a thin “wire” as an electrode, which passes through the workpiece and erodes the material via discharges. Next, hole drilling EDM uses a rotating hollow tube made with copper or brass, and the dielectric flows inside the tube. The size of the tube or hole can be as small as 0.1 mm.

What is CNC Machining?

Computer Numerical Control or CNC machining involves the use of computer-controlled tools; they move along a pre-determined tool path for material removal. Subsequently, other movements and auxiliary systems are also controlled by digital instructions. It significantly reduces human intervention and improves production accuracy.

CNC machining services include several types of machining operations, cutting, milling, facing, profiling, drilling, threading, etc. Basically, everything that is required to convert a raw material workpiece into complex geometrical shapes.

You can shape a wide variety of materials with CNC machining, including metals, alloys, composites, plastics, woods, and ceramics. However, specialized tool coatings are required for hard materials. Subsequently, some extremely hard materials are impossible to process with machining, such as hardened tool steel and tungsten alloys with over 45 Rockwell hardness.

EDM vs CNC Machining: Key Differences

EDM and CNC machining are two different manufacturing methods, used for different purposes.EDM creates complex features and fine details, even in hard or difficult-to-machine materials. On the other hand, CNC produces intricate and complex shapes in large volumes.

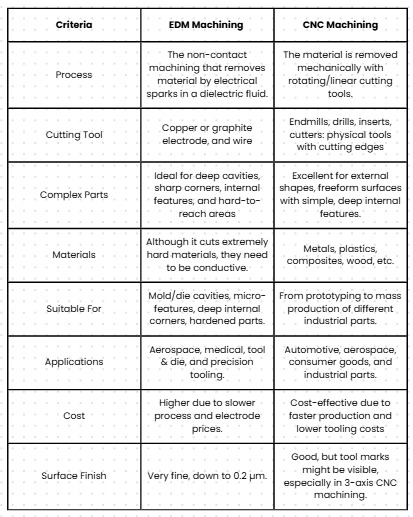

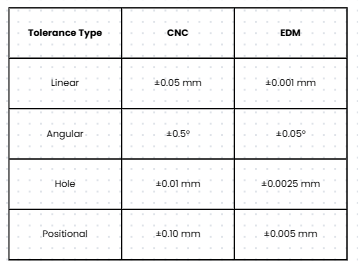

The table below illustrates the common differences in brief.

CNC Vs EDM Machining Tolerances

EDM Machining can achieve much tighter tolerances than CNC milling, drilling, contouring, or any other processes. The table below compares the linear, angular, hole drilling, and positional tolerances.

When to Use EDM Over CNC?

There are certain conditions where using EDM machining instead of CNC milling or any other process makes much more sense, especially when it comes to creating deep cavities, channels, sharp corners, and other complex internal features.

You can choose EDM over CNC in the following five scenarios, but one basic condition is that the workpiece material must be electrically conductive.

Hard Materials: EDM is a non-contact machining, and there is no issue of tool wear. So, it can cut and shape hard materials that are challenging with CNC machining: E.g., hardened steel, tungsten carbide, and nickel-superalloys.

Complex Geometries: Choose EDM if the design has complex geometrical features, such as deep channels, internal contours, and micro-sized components.

Fine As-machined Finish: EDM can achieve a fine surface finish even for micro-sized features, down to 0.2 µm.

For Accurate Parts: The EDM machining tolerances are down to ±0.0025 mm, or even lower. So opt for EDM when you need tight tolerances.

Sharp Internal Corners: If your Design has sharp corners below 0.10 mm, only wire EDM can create this.

Conclusion

The EDM machining can also be controlled by CNC systems. However, standard CNC machining refers to the use of tools with cutting edges, and EDM uses an electrode/wire for material removal inside a dielectric medium.

The CNC manufacturing process has more extensive use in, whereas EDM has specialized capabilities in micro-features machining. It can also cut, drill, or shape hard materials that are challenging to process with CNC.

You must choose between EDM vs CNC based on the design complexity and micro-features. Additionally, it is also possible to use both techniques if your design requires both heavy machining and intricate internal features.

FAQ

Is EDM more expensive than CNC?

Yes, typically per-part production cost of EDM is expensive than CNC due to slow cycles and electrode cost. However, the cost is justified for complex shapes and hard materials.

How accurate is EDM machining?

EDM machining can produce accurate parts with a tolerance of ±0.001 mm, or even lower.

What are the types of EDM?

The types of EDM are wire-cut EDM, Sinker EDM, and hole drilling EDM. Other Variants are either specialized for certain applications, like Micro EDM.

What makes EDM different?

The key distinct feature of EDM from other conventional machining processes is that it uses non-contact mechanical removal. The tool does not physically contact the workpiece; instead, electrical discharges are responsible for material removal.

Is CNC cutting expensive?

CNC cutting is less costly than EDM. The exact machining cost depends on material, complexity, cycle time, setup, and production volume.

HOW DO YOU FEEL ABOUT FASHION?

COMMENT OR TAKE OUR PAGE READER SURVEY

Featured

When investing in quartz countertops, choosing the right warranty and care package is just as important as selecting the color and finish.