Reframing the Future: Inside Paloceras’ MicroFactory and the New Era of Eyewear Innovation

By PAGE Editor

At a moment when much of the eyewear industry remains tethered to long supply chains and distant manufacturing hubs, Paloceras is proposing a different future—one rooted in locality, precision, and technological maturity. With the opening of its MicroFactory in Helsinki on January 5, 2026, the Finnish eyewear company sets a new benchmark for how high-end optical frames can be designed, produced, and finished under one roof.

The MicroFactory represents a radical compression of time and distance. What once took up to twelve months to move from concept to production can now be realized in as little as two weeks. This accelerated timeline enables Paloceras to work fluidly between experimental, limited-edition runs and larger, more refined batches—without sacrificing quality or intention. In an industry often forced to choose between craftsmanship and scalability, the MicroFactory bridges both.

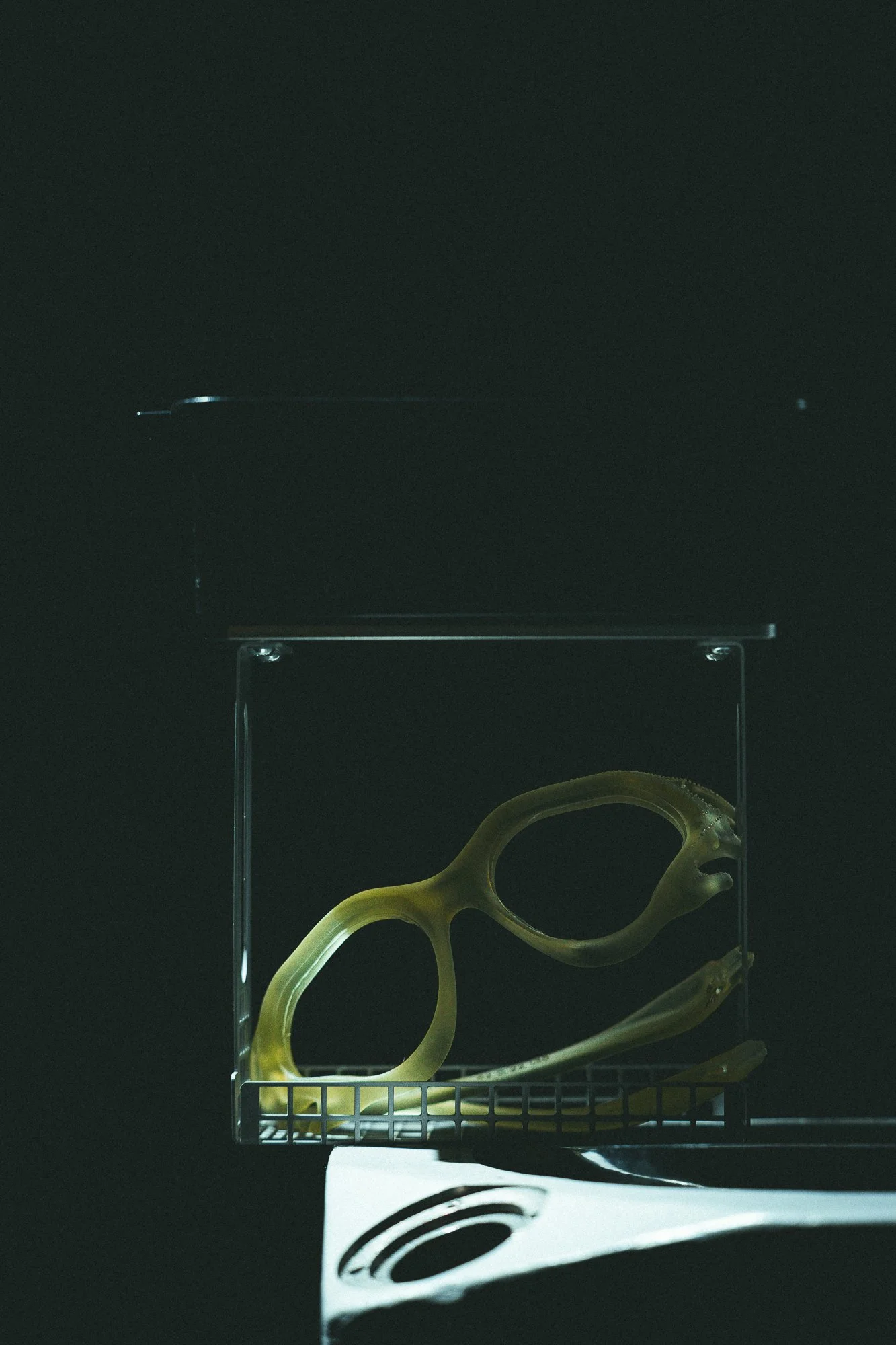

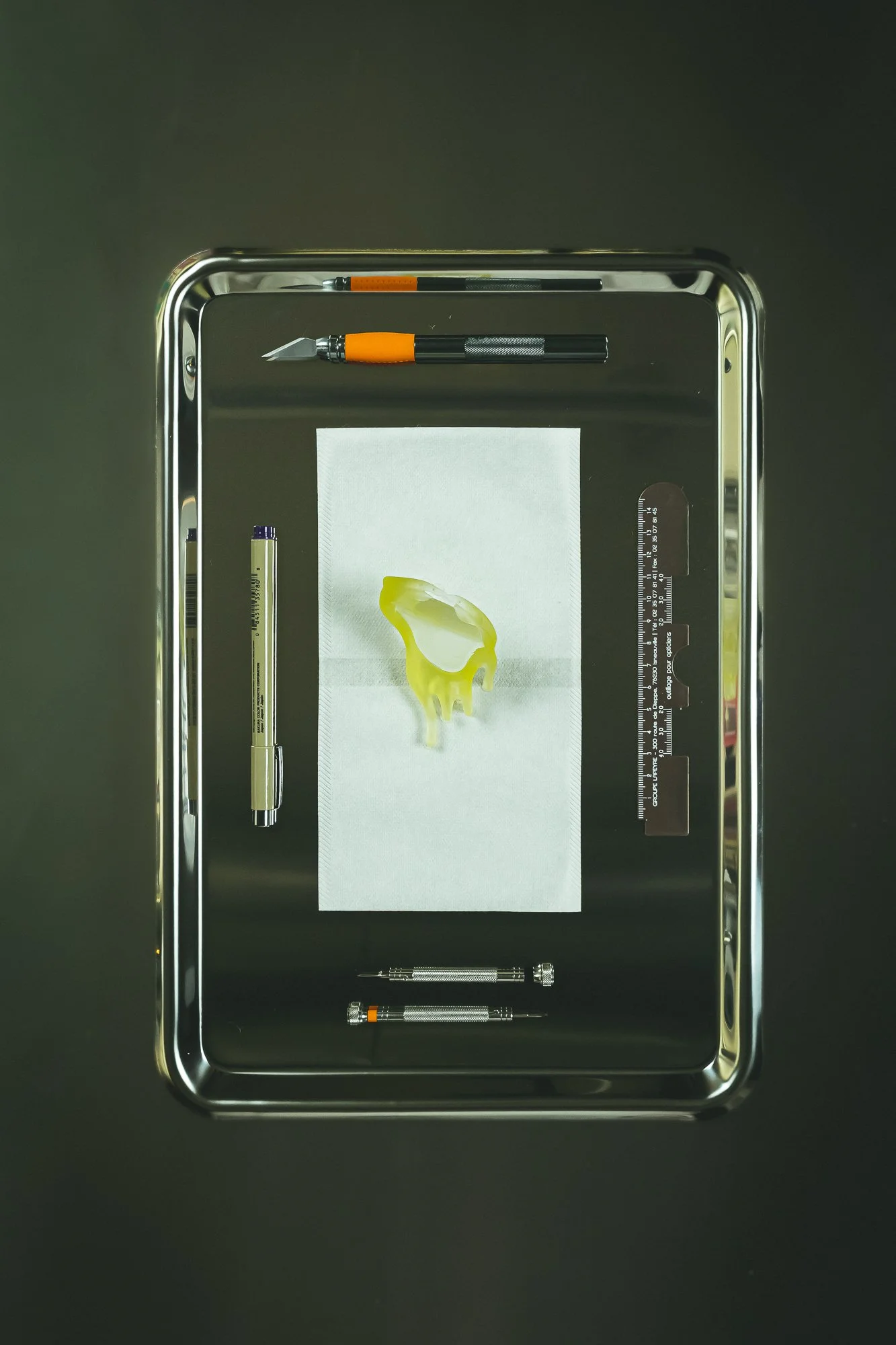

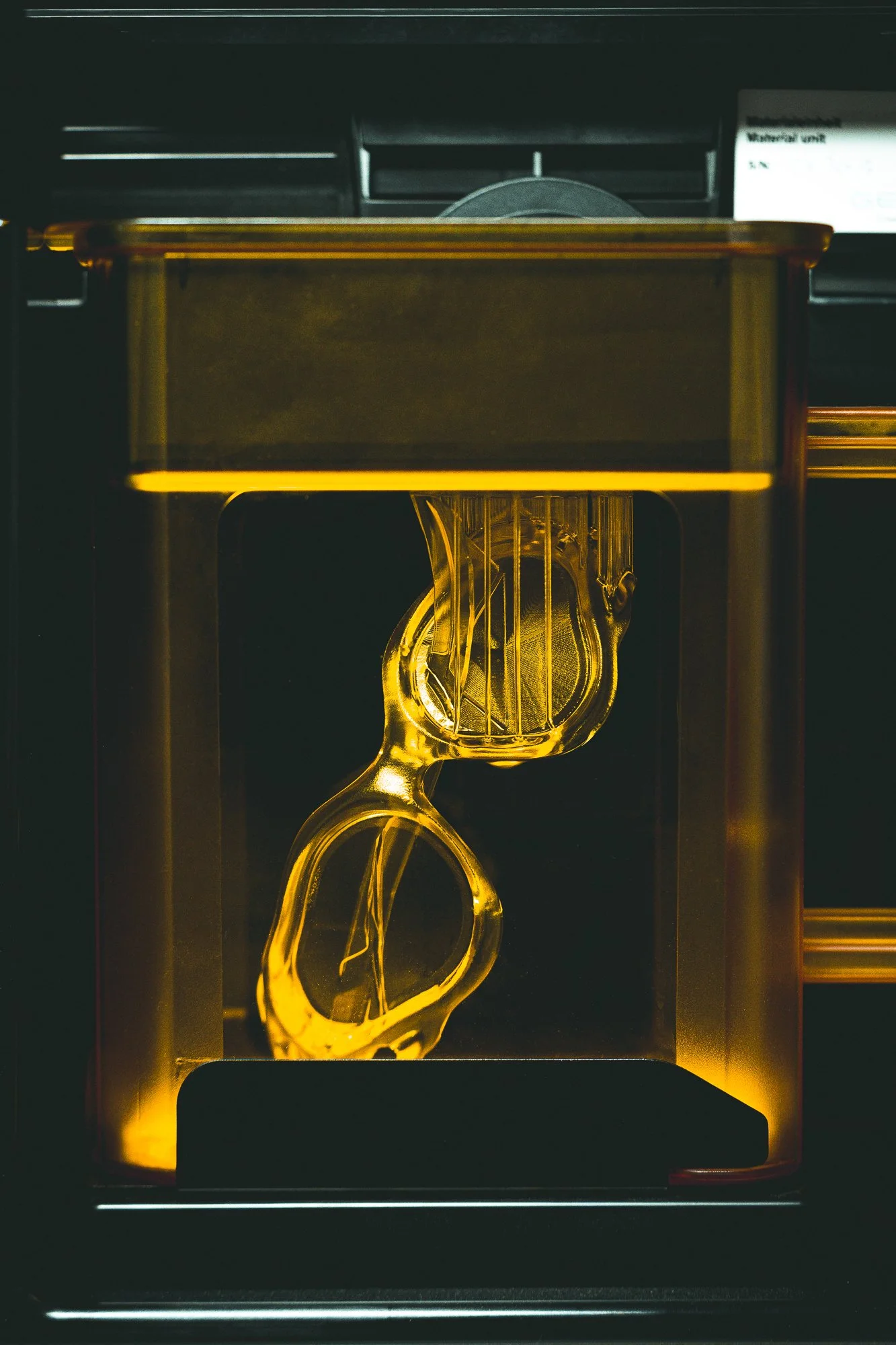

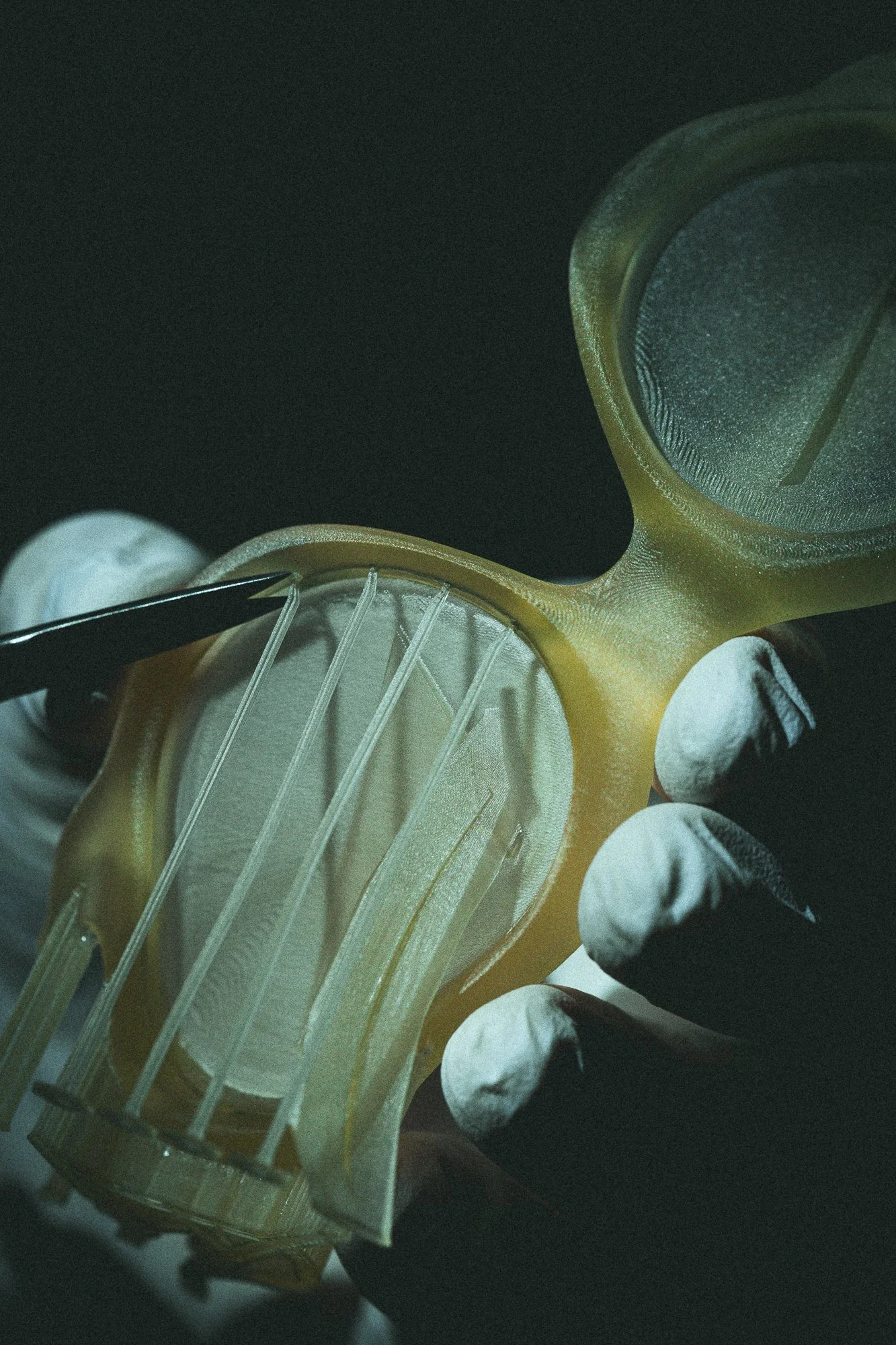

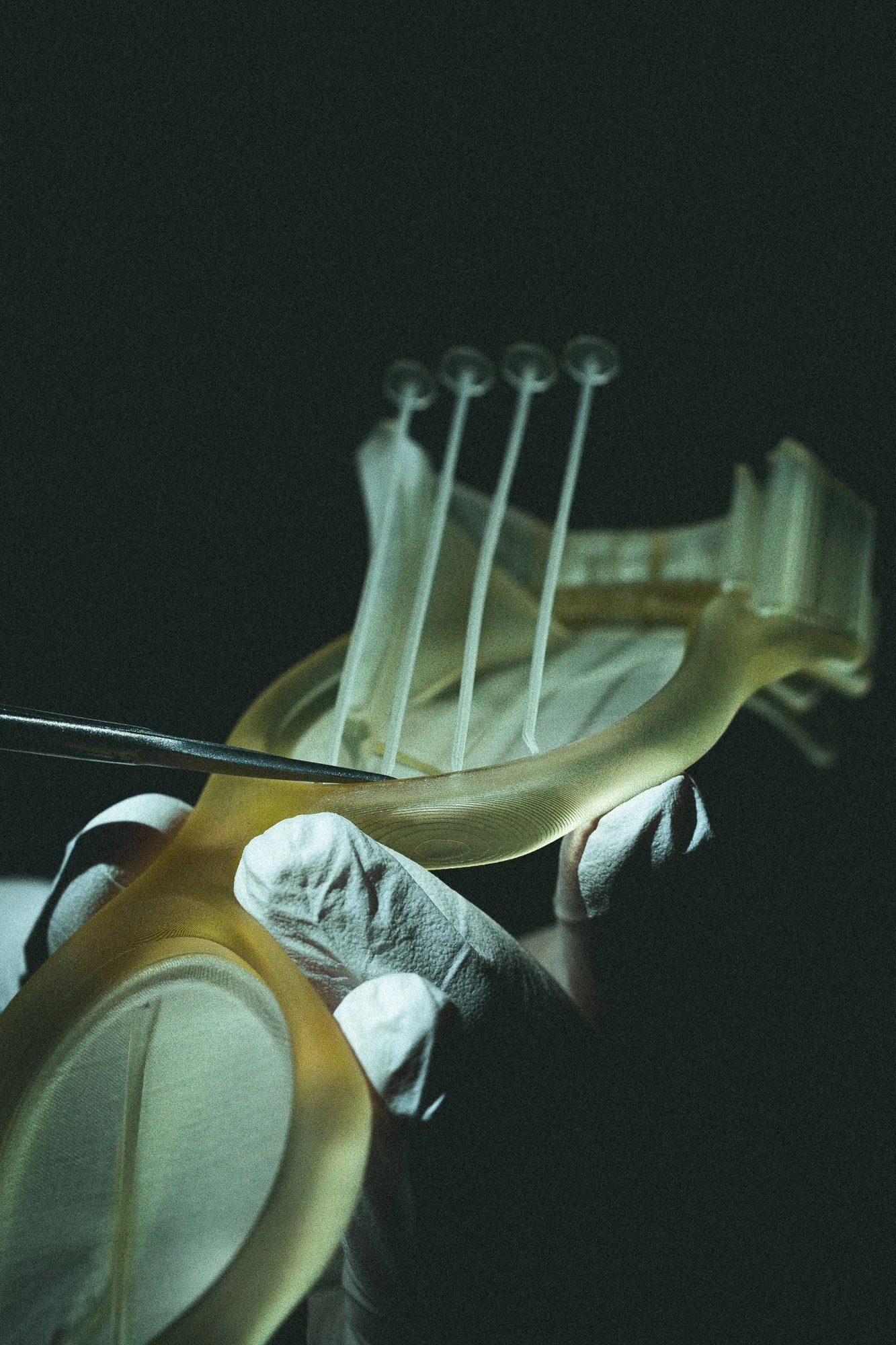

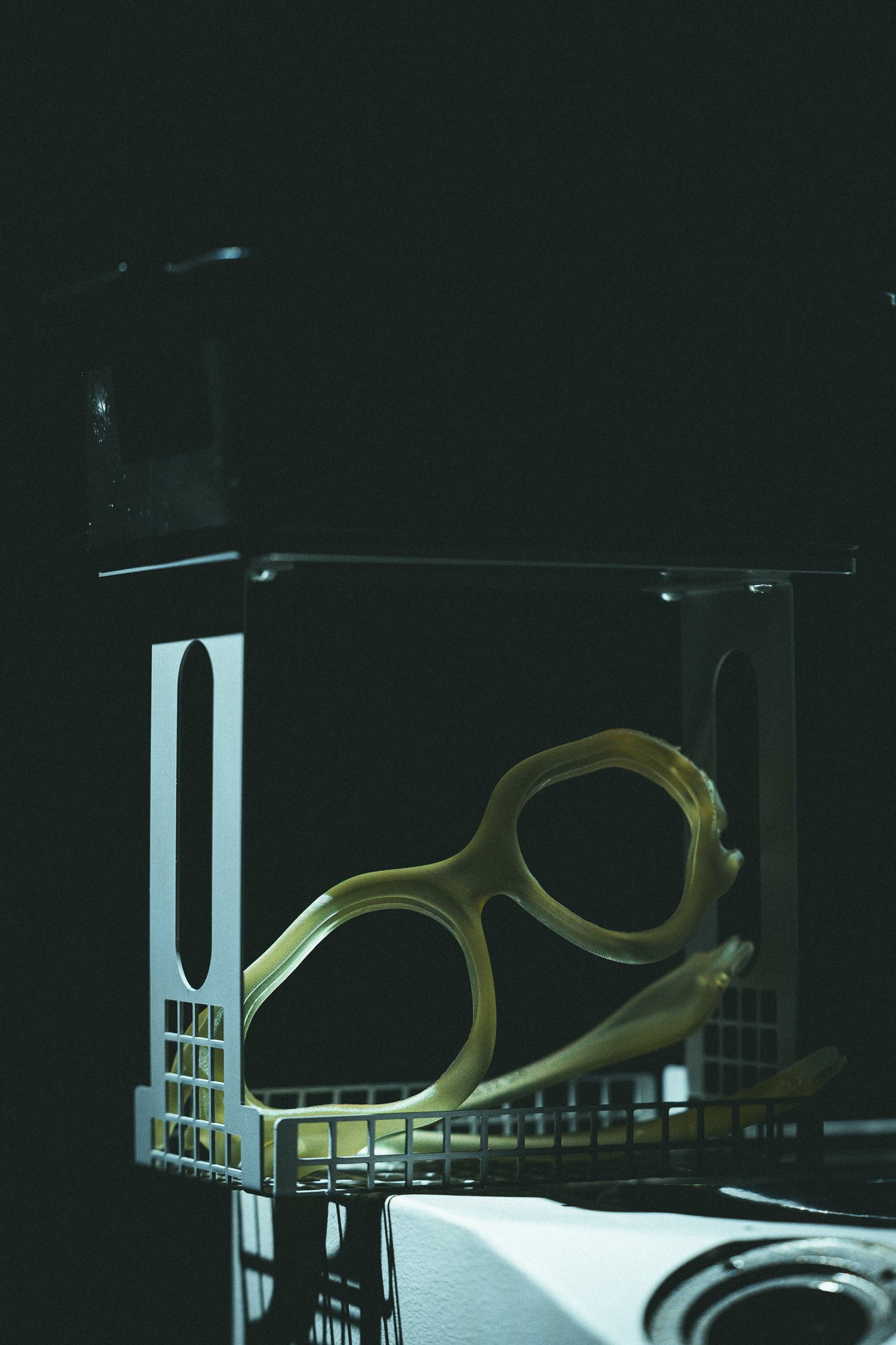

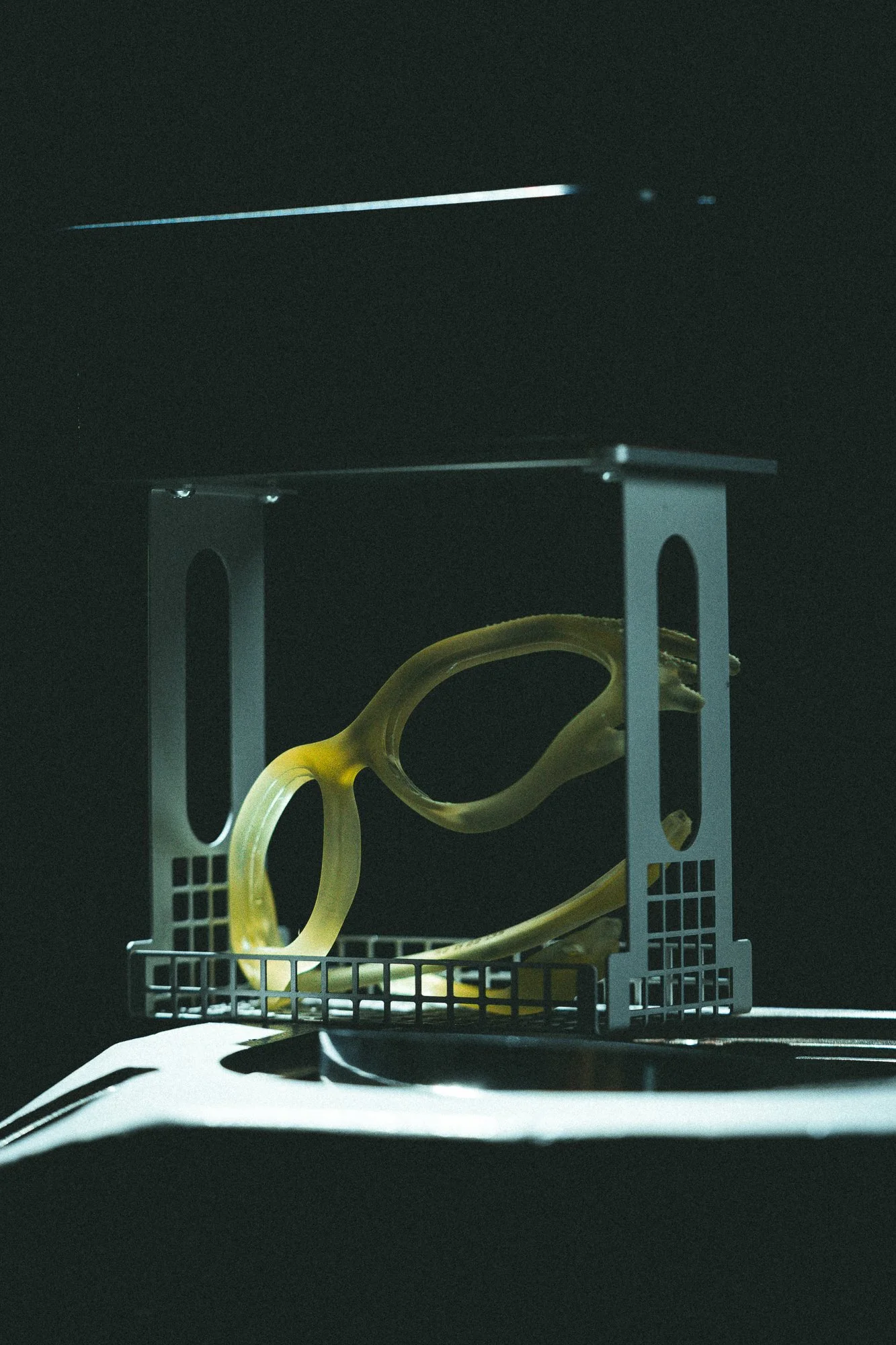

Inside the Helsinki facility, eyewear frames begin as digital models before taking physical form through next-generation 3D printing technology. From there, each piece is hand-sculpted, smoothed, and finished by skilled artisans. The result is a hybrid process that preserves the tactile depth and individuality of traditional craft while achieving the consistency and precision required for larger-scale production. It is innovation not as spectacle, but as structure—quietly reshaping how things are made.

Crucially, Paloceras’ approach is also about control and responsibility. By concentrating modelling, printing, and finishing locally, the brand maintains full oversight of materials, quality, and energy use. This localized production model favors deliberation over volume, aligning with a broader shift toward more considered manufacturing practices in luxury and design.

“Bringing precision-made production, Finnish manufacturing and full in-house control together feels genuinely new,” says Erwin Laiho, Industrial Designer and head of the Paloceras MicroFactory. “It allows continuous refinement, where experimentation and consistency develop in parallel.” His words capture the ethos of the space: a living workshop where iteration is constant and improvement is built into the process.

The MicroFactory also signals a return of optical production to Northern Europe—an area once central to eyewear craftsmanship but largely sidelined as manufacturing moved elsewhere. Advances in 3D printing have finally reached industry-level standards, making this return not just symbolic, but viable. For Paloceras, this technological turning point has been years in the making.

“We have explored 3D printing for years, but the quality was never at the level we demanded,” explains Mika Matikainen, Co-founder and Creative Director of Paloceras. “The technology has now matured.” That maturation was proven with Hydroceras, the brand’s first 3D-printed frame, which debuted to critical and commercial success. After being shown in Paris, opticians around the world placed orders, validating both the design and the production method.

Following a sold-out debut, Hydroceras returns in December 2025 as a fully “Made in Helsinki” edition, featuring refined details and two new colorways. Looking ahead, the MicroFactory will serve as the foundation for Paloceras’ future ambitions, supporting new frame forms, bespoke commissions, and artist-led collaborations beginning in 2026.

In an industry often defined by tradition or scale, Paloceras’ MicroFactory introduces a third path—where advanced manufacturing and human touch coexist, and where innovation is measured not just by speed or novelty, but by intention. It is a model that doesn’t simply modernize eyewear production, but thoughtfully reimagines it.

HOW DO YOU FEEL ABOUT FASHION?

COMMENT OR TAKE OUR PAGE READER SURVEY

Featured

A relaxed guide to sustainable resort wear: easy silhouettes, breathable fabrics, and versatile styles designed for beach days, slow mornings, and late evenings.