How Modern Fashion Shapes High-Performance Gear – 7 Essentials for Racing Suits

By PAGE Editor

The intersection of cutting-edge fashion and high-performance racing gear has revolutionized the way athletes approach their equipment. Gone are the days when racing suits were merely functional; today, they represent a sophisticated blend of technology, style, and performance optimization that can make the critical difference between victory and defeat.

According to a market research report by Grand View Research, the global sportswear market size was valued at USD 231.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This robust growth underscores the increasing importance of precision-engineered racing suits that push the boundaries of human performance.

The following seven essentials reveal how modern fashion has transformed racing suits from simple protective gear to high-tech performance enhancers that athletes rely on to gain that crucial competitive edge.

The Evolution of Racing Fashion

In the early days of motorsport, drivers wore little more than everyday clothing with minimal protection. As speeds increased and safety concerns grew, racing suits evolved into specialized garments. The modern racing suit emerged in the 1960s and 1970s with the introduction of fire-resistant materials, but these early suits prioritized function over fashion, often appearing bulky and utilitarian.

Fast forward to today, and racing suits have become iconic fashion statements that simultaneously push the boundaries of performance technology. Brands like Alpinestars, Sparco, and OMP have revolutionized the industry by collaborating with fashion designers and material scientists to create gear that doesn't compromise on safety, performance, or style.

The journey from functional clothing to performance fashion wasn't straightforward. In the 1980s, as motorsport gained wider television coverage, the visual appeal of racing suits began to matter more. Team colors, sponsor logos, and distinctive designs became crucial elements of racing identity. By the 1990s, manufacturers began experimenting with more tailored cuts and lighter materials that enhanced both appearance and performance. This period marked the beginning of truly integrated design thinking, where aesthetics and function were considered simultaneously rather than sequentially.

The 7 Essential Elements of Modern Racing Suits

1. Advanced Fire-Resistant Materials

The foundation of any racing suit is its fire resistance. Modern suits utilize sophisticated materials like Nomex®, Kevlar®, and carbon fiber weaves that provide protection while maintaining breathability and comfort. These materials must meet rigorous safety standards such as FIA 8856-2018 or SFI 3.2A/5 certification, which test resistance to direct flame and heat transfer. The latest innovations include multi-layer constructions that can withstand temperatures over 800°C for more than 11 seconds, providing crucial escape time in the event of a fire.

What makes modern suits remarkable is how these technically demanding materials are now engineered to be lightweight and flexible, weighing as little as 250 grams per square meter while maintaining their protective properties. The molecular structure of these fabrics represents a triumph of materials science, with aramid fibers that expand when exposed to heat, creating an insulating barrier between the flame and the driver's skin.

The evolution of these materials has been driven by catastrophic incidents in racing history. After Niki Lauda's near-fatal crash and fire at the 1976 German Grand Prix, manufacturers redoubled efforts to improve fire resistance without sacrificing mobility. More recently, Romain Grosjean's fiery crash at the 2020 Bahrain Grand Prix, from which he escaped with minor burns despite being engulfed in flames for nearly 30 seconds, demonstrated the life-saving capabilities of modern racing suit materials.

2. Ergonomic Design and Pre-Curved Architecture

Today's racing suits feature sophisticated ergonomic designs with pre-curved sleeves and legs that mirror the seated driving position. This "second skin" approach eliminates excess material that could bunch up or create pressure points during long races. Engineers now use motion capture technology to analyze driver movements during competition, identifying high-stress points and areas requiring maximum flexibility. The resulting designs incorporate floating sleeves that allow full arm movement without pulling at the torso, and stretch panels strategically placed at joints and high-movement areas.

Micro-adjustments at wrists and ankles enable a personalized fit that prevents material from bunching up inside gloves or shoes. Anatomically correct cutting reduces fatigue during extended wear, a crucial factor in endurance races like the 24 Hours of Le Mans where drivers may spend hours at a time in the cockpit. Some manufacturers have even developed different patterns for left-hand and right-hand drive vehicles, accounting for the subtle differences in posture and movement patterns.

The influence of high fashion is particularly evident in the tailoring of modern suits. Racing apparel manufacturers regularly consult with fashion designers who bring expertise in creating garments that flatter the human form while accommodating extreme movement requirements. This cross-industry collaboration has resulted in racing suits with distinctly fashion-forward silhouettes that enhance driver presence both in and out of the car.

3. Moisture Management and Thermoregulation

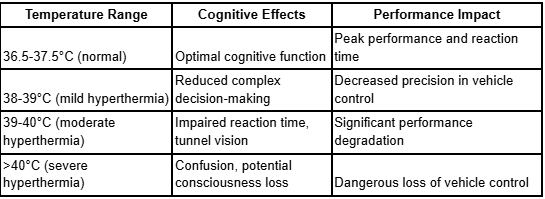

Racing drivers face extreme temperature challenges, with cockpit temperatures regularly exceeding 50°C (122°F) in motorsports like Formula 1. Modern suits address this with advanced thermoregulation systems that include moisture-wicking inner layers, breathable membrane technologies, and strategically placed ventilation channels. These systems work together to maintain a microclimate between the suit and the driver's body that optimizes performance and reduces fatigue.

Companies like Puma and Alpinestars have developed proprietary cooling systems that can reduce core body temperature by up to 5°C, significantly improving driver focus and endurance during races. The science behind these systems draws from research in space suits and military applications, adapted specifically for the unique requirements of motorsport. Some cutting-edge suits now incorporate phase-change materials (PCMs) that absorb excess heat when the driver's body temperature rises, storing it and then releasing it when temperatures drop, providing a natural cooling effect.

The cognitive impact of effective temperature regulation cannot be overstated. Research has shown that even minor overheating can reduce reaction times and decision-making capabilities, critical factors in high-speed racing where milliseconds and millimeters make the difference between victory and disaster. By keeping drivers in their optimal temperature range, modern suits directly contribute to performance and safety on track.

4. Weight Optimization

Every gram matters in racing, and modern suits have undergone dramatic weight reduction while maintaining or improving protective qualities. Today's top-tier suits weigh between 1.2-1.5kg, nearly half the weight of suits from just 15 years ago. This remarkable achievement comes from ultra-lightweight fiber blends with molecular-level engineering and precision manufacturing that eliminates unnecessary material without compromising structural integrity.

The psychological advantage of a lightweight suit cannot be overstated, as it creates a feeling of freedom that translates directly to confidence on the track. Drivers report that lighter suits reduce fatigue during long races and enable more precise car control through improved proprioception, the awareness of body position and movement. The weight reduction journey has paralleled developments in other high-performance fields like aerospace, where materials must deliver maximum strength with minimum mass.

Carbon nanotube reinforcement represents the cutting edge of weight optimization, with some prototype suits incorporating these microscopic structures to maintain strength while reducing material density. The manufacturing process for these advanced suits has become increasingly precise, with laser-cutting technologies that can remove material with sub-millimeter accuracy, further reducing weight while preserving essential protective zones.

5. Personalized Fit Technology

Gone are the days of off-the-rack racing suits. Today's high-performance gear utilizes advanced fitting technologies that begin with 3D body scanning to create digital models of each driver's physique. These scans capture thousands of data points that inform computer-aided design systems, optimizing suit dimensions for individual body mechanics and preferences. Custom stretch zones are calibrated to a driver's unique movement patterns, while pressure mapping identifies and eliminates potential discomfort points.

Teams in Formula 1 and other high-level motorsports now create bespoke suits for each driver, with multiple fittings and adjustments throughout a season as body composition and preferences change. This personalization extends beyond mere comfort; a precisely fitted suit reduces energy expenditure by eliminating the need to compensate for ill-fitting gear, allowing drivers to focus entirely on vehicle control and race strategy.

The bespoke approach has trickled down from elite motorsport to amateur and club-level racing, with many manufacturers now offering semi-custom options. Drivers can select from a range of adjustments and modifications to standard patterns, bringing professional-level fit to a wider audience. This democratization of custom fit technology represents a significant shift in how racing apparel is conceptualized and marketed, with personalization becoming an expected feature rather than a luxury upgrade.

6. Integrated Biometric Systems

The cutting edge of racing suit technology now includes integrated biometric monitoring systems woven directly into the fabric. Heart rate sensors, temperature monitoring systems, hydration level indicators, and muscle fatigue sensors transmit real-time data to pit crews and medical teams, allowing for informed strategy decisions and improved safety monitoring. The integration is so seamless that drivers report no awareness of the sensors during races.

These systems have revolutionized race strategy by providing objective data about driver condition throughout events. For example, team managers can now make evidence-based decisions about driver changes in endurance races, swapping drivers when biometric data indicates fatigue is reaching critical levels rather than relying on predetermined schedules or subjective assessments. Medical teams can monitor vital signs continuously, enabling proactive intervention before physical stress becomes dangerous.

The development of these integrated systems has required unprecedented collaboration between electronics manufacturers, textile engineers, data scientists, and medical professionals. The resulting technology represents a new frontier in wearable health monitoring, with applications extending far beyond motorsport into healthcare, space exploration, and extreme environment operations.

7. Distinctive Visual Design and Branding

While performance is paramount, the visual design of racing suits plays a crucial role in team identity and sponsor representation. Modern suits employ aerodynamic color blocking that visually emphasizes speed and movement while enhancing driver recognition during broadcasts. Strategic logo placement maximizes visibility while maintaining aesthetic balance, a critical consideration for sponsors investing millions in team partnerships.

Design elements are carefully crafted to translate effectively between physical suits and digital/broadcast media, with colors calibrated specifically for television cameras and online streaming. Color psychology applications enhance brand recognition and driver presence, with teams selecting palettes that convey specific attributes: red for passion and aggression, blue for technical precision and calm authority, black for power and sophistication.

Top teams employ fashion designers alongside technical engineers to ensure their racing suits project the right image while maintaining all performance characteristics. These designers often draw inspiration from haute couture and streetwear trends, incorporating contemporary fashion elements that keep racing aesthetics current and culturally relevant. The result is racing apparel that functions as both high-performance equipment and powerful brand communication tools, blurring the line between technical gear and fashion statement.

Technology Transfer Between Racing and Consumer Fashion

The influence between racing suits and consumer fashion flows in both directions. Racing-inspired design elements regularly appear in mainstream fashion collections, with designers like Prada, Balenciaga, and Off-White incorporating motorsport aesthetics into their runway presentations. Simultaneously, trends from high fashion influence racing suit design, particularly in color selection, pattern cutting, and graphic approaches.

This cross-pollination has accelerated in recent years as social media has elevated the visibility of drivers beyond racing broadcasts. Formula 1 drivers like Lewis Hamilton and Charles Leclerc have become fashion icons in their own right, attending major fashion events and collaborating with luxury brands. Their influence has helped transform racing suits from purely technical equipment to coveted style statements that communicate precision, speed, and cutting-edge innovation.

More substantively, the technical advances developed for racing suits frequently find applications in consumer apparel. Moisture-wicking fabrics first perfected for motorsport now appear in everyday athletic wear, while the ergonomic cutting techniques developed for racing suits influence the construction of high-performance outdoor clothing. Even mainstream fashion has adopted manufacturing processes pioneered in racing apparel, such as bonded seams and laser cutting, techniques that originated as weight-saving measures in motorsport.

Sustainability Challenges and Innovations

As the broader fashion industry grapples with sustainability concerns, racing suit manufacturers face particular challenges. The specialized materials required for safety certification often include synthetic fibers with significant environmental footprints. However, innovation is rapidly addressing these issues through several approaches.

Bio-based aramids derived from renewable resources are beginning to replace traditional petroleum-based fibers, offering comparable protection with reduced environmental impact. Closed-loop manufacturing systems now recover and reprocess waste materials, significantly reducing production emissions. Some manufacturers have pioneered take-back programs that recycle decommissioned racing suits into new products or repurpose materials for non-racing applications.

The durability of modern racing suits also contributes to sustainability efforts. Today's suits are engineered to maintain their protective properties through multiple seasons of use, with modular designs that allow for component replacement rather than complete suit replacement when parts wear out or damage occurs. This approach extends useful life while reducing resource consumption and waste.

The Future of Racing Fashion

As we look ahead, the integration of fashion and function in racing suits continues to accelerate. Emerging technologies promise even more impressive developments, including graphene-infused fabrics that provide unprecedented strength-to-weight ratios and active cooling systems using microfluidics to circulate cooling liquids through the suit. Adaptive materials that change properties in response to temperature or impact are moving from laboratory testing to track implementation, while augmented reality displays integrated into collars and cuffs may soon provide additional driver information without requiring glances at the dashboard.

Perhaps most exciting is the potential for completely personalized performance optimization. Researchers are developing systems that adjust suit properties based on individual physiological responses, creating truly adaptive gear that responds in real-time to changing driver conditions. For instance, ventilation channels might automatically open or close based on body temperature and exertion levels, while compression elements could adjust to optimize blood flow during different race phases.

The fusion of artificial intelligence with racing apparel design promises to accelerate innovation further. AI systems can process vast amounts of performance data to identify subtle relationships between suit design and driver performance that human designers might miss. These insights drive iterative improvements that push the boundaries of what's possible in terms of protection, comfort, and performance enhancement.

HOW DO YOU FEEL ABOUT FASHION?

COMMENT OR TAKE OUR PAGE READER SURVEY

Featured

When investing in quartz countertops, choosing the right warranty and care package is just as important as selecting the color and finish.