Maintenance Tips to Keep Your Wheelchair Lift Running Smoothly

By PAGE Editor

A wheelchair lift is an incredibly important piece of equipment, providing vital access and independence for users at home, in vehicles, or in public spaces. When it's working, it's a seamless part of daily life. But when it fails, it can cause major disruptions and safety concerns.

The key to reliability is consistent, simple maintenance. Just like any other piece of machinery, your Wheelchair Lift requires regular attention to stay in top condition. These preventative steps can help you catch small issues before they become major, costly repairs.

Here are six essential maintenance tips to keep your wheelchair lift running smoothly and safely.

1. Keep it Clean

This is the simplest yet most effective maintenance task. Dirt, debris, and moisture can gum up moving parts, corrode electrical contacts, and obstruct sensors.

Platform: Regularly sweep or vacuum the lift platform to remove dirt, gravel, or leaves.

Controls: Wipe down control panels and switches with a slightly damp cloth. Avoid spraying cleaners directly onto electrical components.

Tracks: If accessible, wipe down the lift's tracks or guide rails to ensure a smooth path.

2. Perform Regular Visual Inspections

You don't need to be a technician to spot potential trouble. Once a week, take a minute to look over your wheelchair lift.

Check for any loose bolts, screws, or safety barriers.

Look for signs of wear and tear on cables, belts, or hydraulic hoses.

Inspect for any fluid leaks, which could indicate a problem with a hydraulic system.

Ensure the platform and any folding ramps are aligned correctly.

3. Lubricate Moving Parts

A properly lubricated Wheelchair Lift operates more quietly and smoothly, reducing wear on motors and gears.

Consult Your Manual: This is critical. Your owner's manual will specify what to lubricate (e.g., pivot points, hinges, gears), what lubricant to use (grease, silicone spray, etc.), and how often to apply it.

Warning: Using the wrong lubricant can attract dirt and actually increase wear. Always follow the manufacturer's guidance.

4. Check and Maintain the Battery

Many wheelchair lifts, especially in vehicles, run on a battery system. A dead battery means a non-functional lift.

Charge Fully: Ensure the lift's battery (or the vehicle's battery, if it's linked) is regularly and fully charged.

Clean Terminals: Check the battery terminals for any corrosion (a white, powdery substance). If you see any, disconnect the battery (if you are comfortable doing so) and clean the terminals with a battery cleaning solution or a mixture of baking soda and water. Ensure they are dry before reconnecting.

5. Test the Controls and Safety Features

On a regular basis (e.g., weekly), run the lift through a full cycle without a passenger.

Smooth Operation: Listen for any unusual grinding, squeaking, or stuttering sounds. Watch for jerky movements.

Emergency Stop: Test the emergency stop button to ensure it functions immediately.

Safety Barriers: If your lift has automatic safety barriers or flaps, make sure they deploy correctly as the lift moves.

6. Schedule Professional Servicing

While these DIY tips are essential, they don't replace the need for professional service. A certified technician has the tools and expertise to inspect the complex electrical, mechanical, and hydraulic systems of your Wheelchair Lift.

Plan to have your lift professionally inspected and serviced at least once a year. This is the best way to ensure all components are in safe working order and to extend the life of your investment.

Conclusion

By integrating these simple maintenance habits into your routine, you can ensure your wheelchair lift remains a dependable and safe tool for years to come.

Frequently Asked Questions (FAQ)

How often should I get my lift professionally serviced?

While once a year is the general rule, you should consult your owner's manual. If the lift is used very frequently (multiple times per day) or is exposed to harsh weather conditions, servicing it every six months is a wise precaution.

What should I do if my lift stops working suddenly?

First, ensure the emergency stop button is not engaged. Check that the power is on and that the battery is charged. If it's a vehicle lift, ensure the vehicle is on and any safety interlocks (like the handbrake) are engaged. If these simple checks don't solve the problem, consult your manual for troubleshooting or call a professional technician. Do not attempt to force the lift to move.

Can I use a generic lubricant like WD-40 on my lift?

It is strongly advised not to. WD-40 is a water displacer and solvent, not a long-term lubricant. It can strip away the necessary grease and attract dust. Always use the specific type of grease or silicone lubricant recommended by the lift manufacturer.

Is it safe to operate the lift in heavy rain or snow?

While most outdoor lifts are designed to be weather-resistant, heavy rain, snow, or ice can still pose a risk. Ensure the platform is clear of snow or ice to prevent slipping. If the lift is operating slowly or making unusual noises in extreme weather, it's best to avoid using it until the weather improves and you can inspect it.

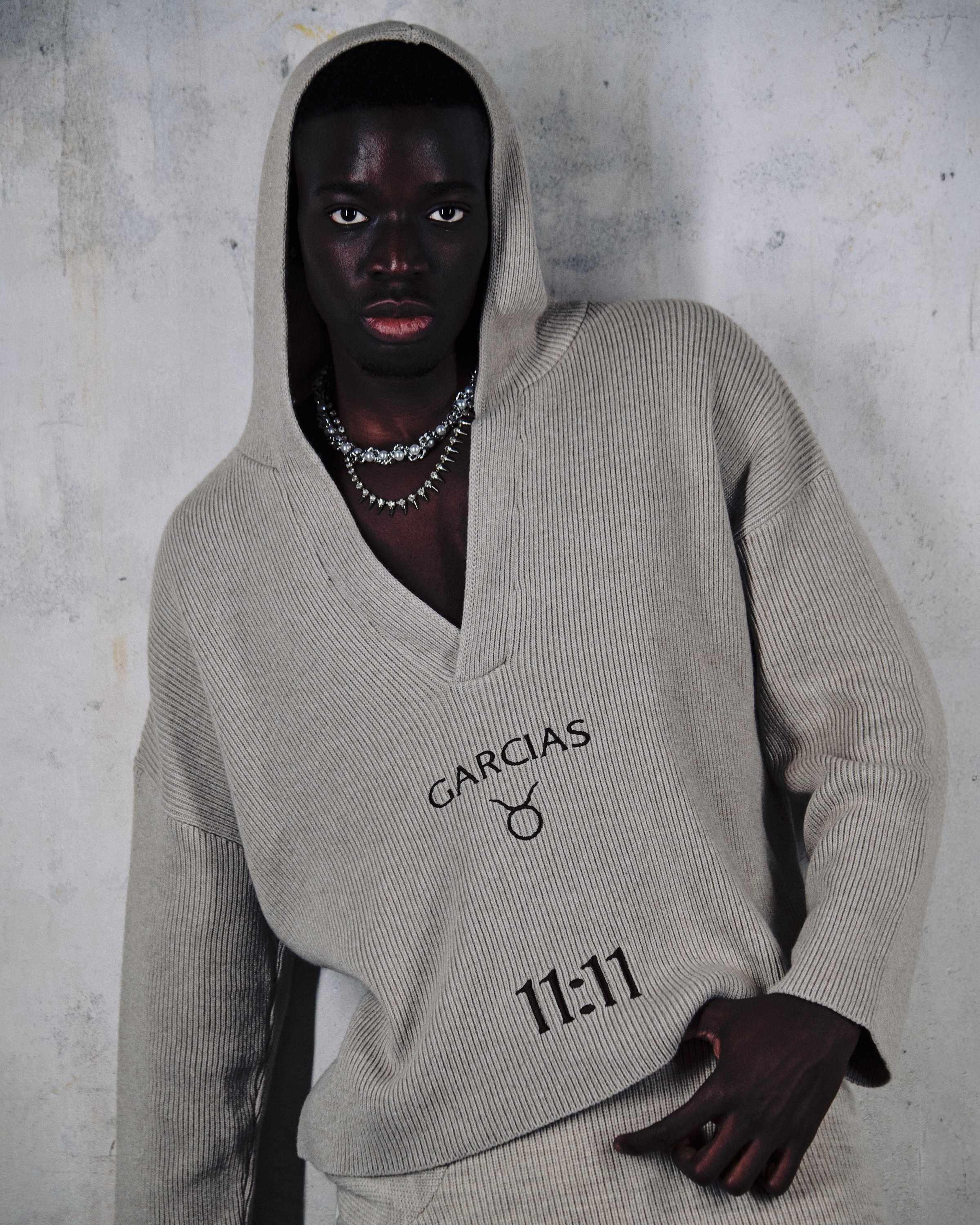

HOW DO YOU FEEL ABOUT FASHION?

COMMENT OR TAKE OUR PAGE READER SURVEY

Featured

The difference between a good result and a breathtaking one lies in the details